34

ACCESS IN ACTION • AUGUST 2016

ACCESS in ACTION

“For Snorkel, this has and continues to

present challenges for our engineering

team, as they work to incorporate the

latest technologies into existing products,

ensuring compliance with the various

regional standards that are not always

aligned,” Matthew said.

“Snorkel engineers have undertaken

significant research and considered

many emission lowering options for

diesel powered lifts. These options have

included the reduction of their engines

in size and alternative fuel/power source

options. They also analysed whether a

smaller, compliant engine could be used,

that could charge batteries or provide

supplemental power.

“Our engineers found in some cases,

adjustments to the gearing would

allow us to use a lower output engine

to achieve or exceed the performance

from a higher output engine. This

results in lower emissions, satisfactory

performance, and simpler engine

maintenance.”

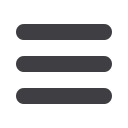

The Snorkel A46JRT diesel articulated

boom lift is one of the models fitted with

a lower output engine. This rough terrain

Meeting changing emissions standards

lift was previously powered by 45hp

diesel engine, but has now been reduced

to a 24.8hp diesel engine.

“By using electronic controls that monitor

the engine speed, we have been able to

reduce hydraulic demand on the engine

in proportion to the amount of power

available. The end result is a machine

that complements an operator’s natural

instinct to operate in low speed over

rough terrain,” he said.

Snorkel’s approach to meeting emission

regulations has also been adopted by

sister company, Xtreme Manufacturing.

“Where possible, Xtreme is utilising large

displacement, governed diesel engines

rated below 75hp. These engines provide

normal torque output, but are limited to

not exceed 74hp,” Matthew said.

“With optimised tuning of the

transmission, axles gearing and

hydraulics systems, the telehandlers can

performs as well as with larger output

engines, but without the complexity of

Diesel Exhaust Fluid (DEF).

“Another option for lowering emissions

to meet increasing regulations is the use

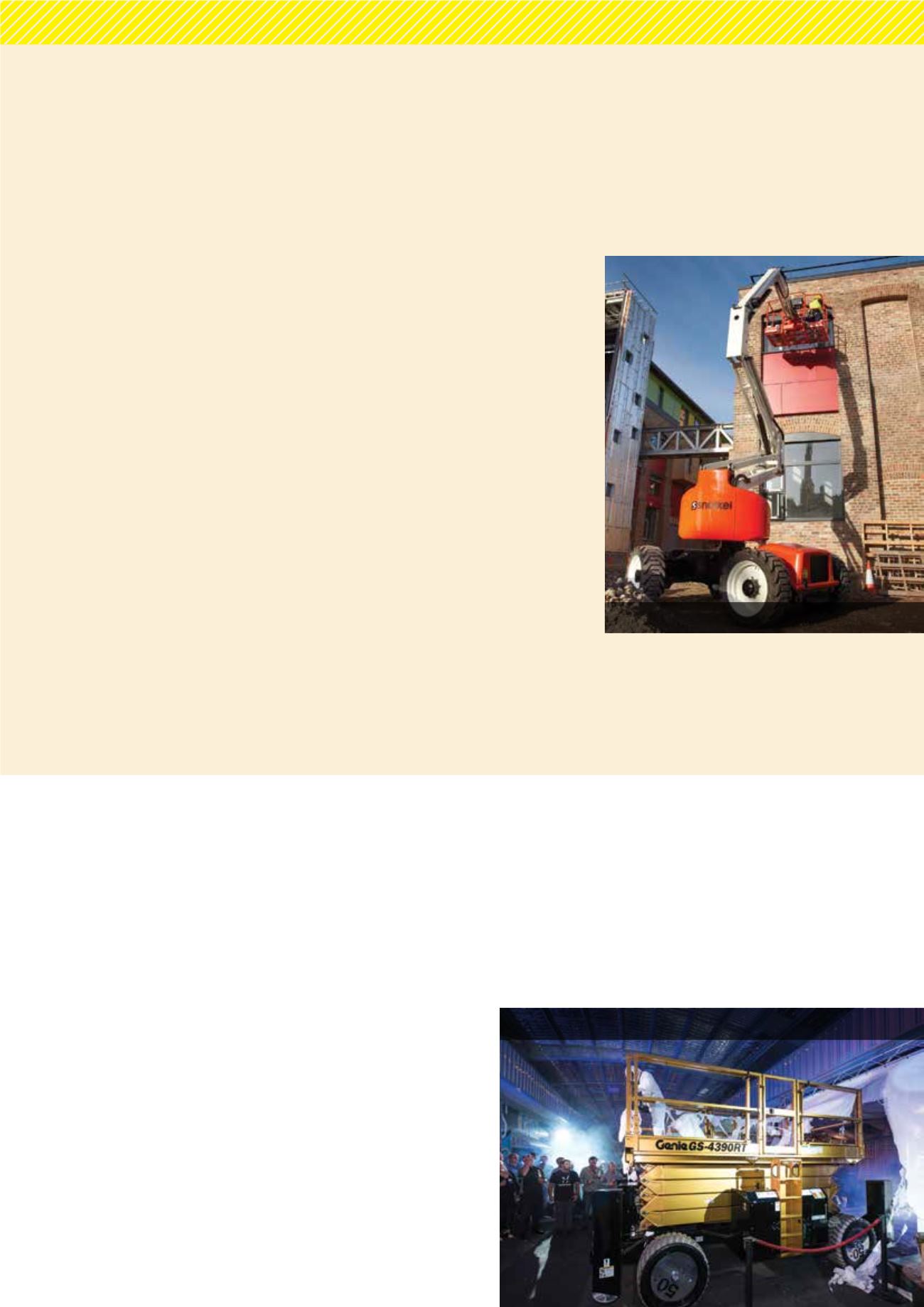

The refurbished 10-year-old anniversary-

themed scissor lift was unveiled at the

Genie annual customer appreciation

night held on Australia’s Gold Coast

in May. The event, held at the Miami

Marketta, was attended by Matt Fearon,

Genie President, Terex AWP and Jim

Barr, Genie Vice President and General

Manager, Asia Pacific, Terex AWP.

“As part of our company’s 50th year

initiative, the one-of-a-kind gold-painted

Genie GS-4390 RT scissor lift was rebuilt

by a large number of the Genie team

in Australia, with a massive 4.4 litre V8

engine,” Brad Lawrence, Genie General

Manager Australia, Terex AWP said.

Mitch Ely, National Operations Manager,

Terex AWP, who coordinated the rebuild,

Aussie scissor lift star attraction at 50-year celebration

A Genie GS-4390 RT scissor lift, major inspected and refurbished in Australia and painted

in gold, headed to the US to be showcased at the Genie headquarters in Redmond,

Washington for the company’s 50 year celebrations.

said the Genie GS-4390 RT scissor lift is

10-year inspected and fully refurbished.

In total, 61 members of the Genie

team across Australia were involved in

rebuilding the scissor lift.

“The machine started in

Melbourne, where the team

disassembled it, while the

team in Sydney refurbished

the impressive scissor

stack,” Mitch said.

“The team in Adelaide

built the amazing wheels

and the Perth heavy

maintenance team built

the engine. The Brisbane

team reassembled the

machine and commissioned it, while our

senior technician in Darwin played ‘The

Stig’ when the scissor was unveiled.”

Visit: www.terex.com

Engine emission standards for non-road going vehicles are changing, with new

regulations being introduced in various parts of the World, including North America and

this presents challenges for engineering teams, Matthew Elvin, Snorkel CEO, said.

of dual fuel gasoline/propane engines,

as an alternative to diesel. Many of the

engine manufacturers are beginning to

offer solutions for alternative fuels, by

converting existing diesel engines to

accept gasoline or propane.”

Visit: www.ahernaustralia.com.au

Snorkel engineers have considered many emission

lowering options for diesel powered lifts

The golden Genie GS-4390 RT scissor lift is 10-year inspected and

fully refurbished